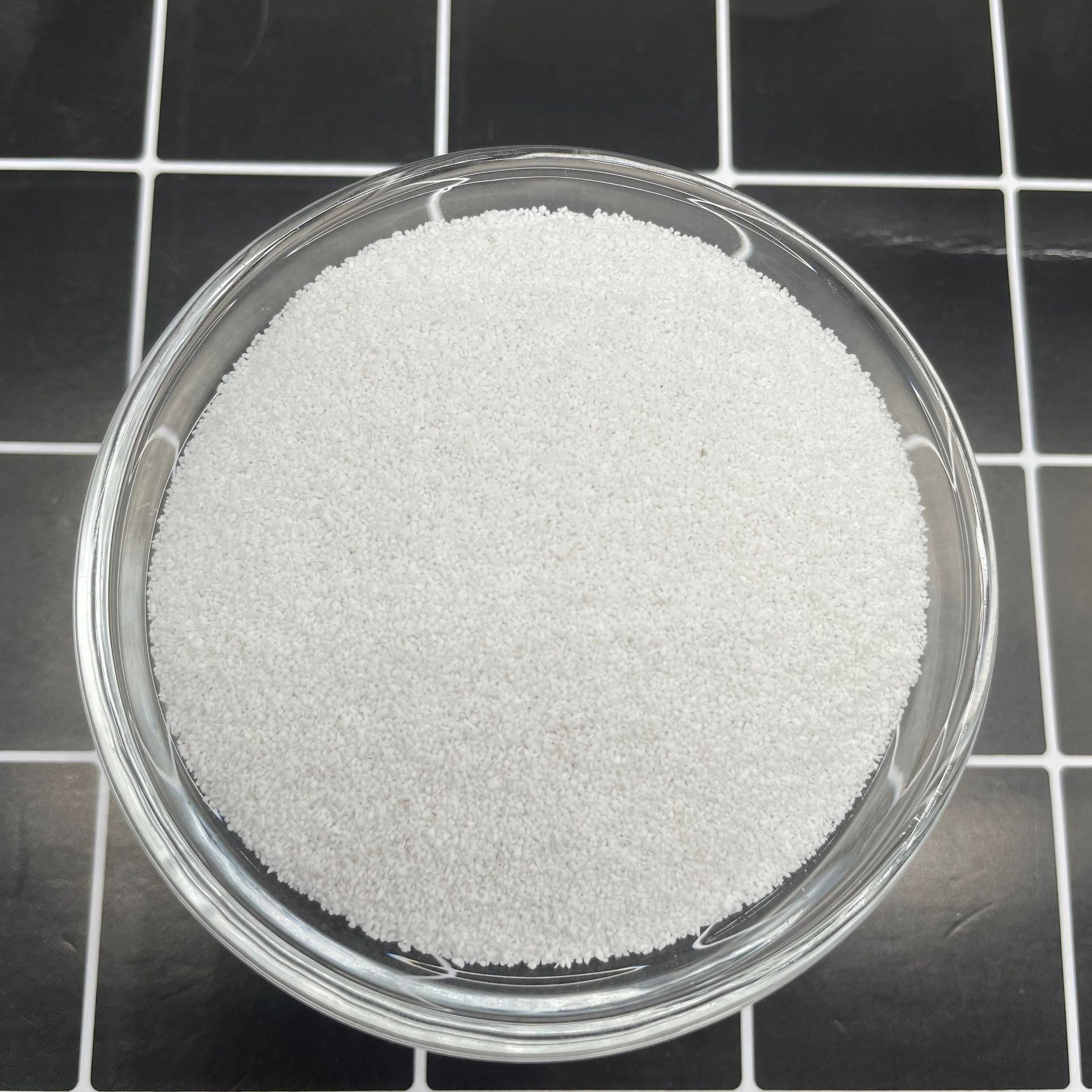

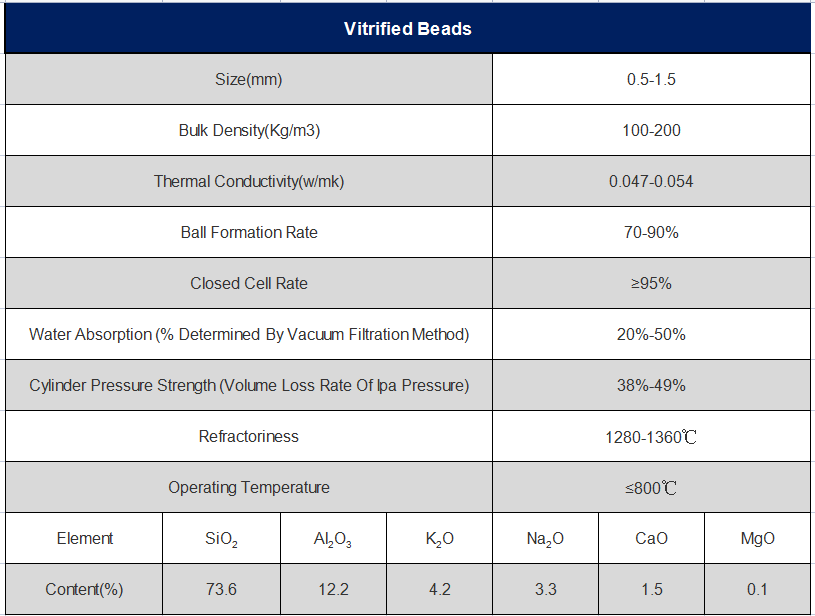

Expanded vitrified beads (also known as Hole-close perlite, Expanded and vitrified small ball) are a new type of inorganic environmentally friendly thermal insulation material. The product is made of selected ore sand with special particle size and expanded under electric furnace heating. Through precise control of temperature and raw material stagnation time, the surface of the product is melted, the pores are closed, and the appearance is microsphere-shaped, the internal porous cavity structure, and the surface glass Closed chemical, smooth luster, and stable physical and chemical properties.

Expanded vitrified beads are an environmentally-friendly new type of inorganic lightweight heat-insulating material. In addition to the excellent performance of light weight, heat preservation, heat insulation, and fire prevention, they also have non-combustibility, high strength, low water absorption, good ease of compatibility and long service life. Long and other advantages.

Due to the surface vitrification forms a certain particle strength, the physical and chemical properties are very stable, the aging and weather resistance is strong, and it has excellent heat insulation, fire protection and sound absorption properties. It is suitable for light filling aggregates and heat insulation, fire protection, sound absorption and heat preservation materials in many fields. . It is widely used in petroleum, chemical, electric power, construction, metallurgy and other industries!

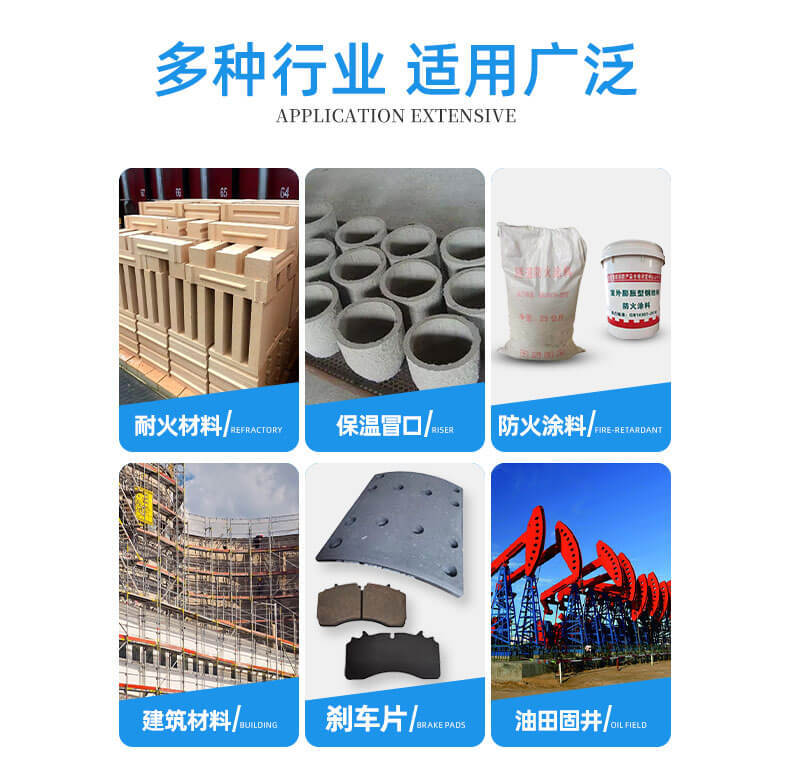

Internal and external wall thermal insulation mortar, thermal insulation putty; lightweight decorative panels, ceiling panels, sound-absorbing panels; thermal insulation coatings; lightweight wall panels; lightweight refractory materials; thermal pipeline thermal insulation; industrial kiln insulation; petroleum and chemical industries; fire-fighting materials.

As a new type of thermal insulation material in the building materials industry, vitrified microspheres are used in wall thermal insulation and light refractory materials industries. They have extremely broad application prospects. They can also replace fly ash, floating beads, glass beads, expanded perlite, The application of many traditional lightweight aggregates such as polyphenylene particles in different industries is widely used in many fields such as industry, agriculture, building materials, chemical industry, smelting, light industry, etc., and the economic benefits are very significant.

20-30 mesh is mostly used for external wall insulation, roof insulation, ground backfilling and leveling, large-area gardening seedling cultivation, loose soil and lock water.

30-50 mesh, mostly used for internal and external wall insulation, roof thermal insulation.

50~70 mesh Expanded vitrified beads are mainly used for building heat preservation and heat insulation, and are important aggregates for making heat preservation mortar. It is also an important aggregate for making refractory bricks. It is also widely used in the production of fireproof coatings.

70~90 mesh Expanded vitrified beads can also be used for building thermal insulation according to needs, mainly for spraying thermal insulation mortar. Production of tunnel fireproof coatings. Filling materials for rubber products.

90~120 mesh Expanded vitrified beads, both 40 mesh perlite floating beads, are currently mainly used in the field of oil cementing, also known as oilfield cementing lightening agent. The low-density cement slurry formulated with the reducing agent has good strength, can reduce the solution force of the annulus liquid column, can satisfy the cementing of the low-pressure and easy-to-leakage layer, and realize the cementing of the long sealing section. The water-soluble polymer in the mud system can absorb the hydration layer, restrain more free water, block the voids between cement particles, and reduce the permeability of the cement filter cake. The mud system has a certain viscosity, the slurry is not easy to be dehydrated, and can further reduce water loss, seal the local loss layer during the cementing process, and effectively reduce the cost. Perlite for oilfield cementing has a particle size range of 10-250μm. It has excellent properties such as light weight, non-toxic, odorless, corrosion resistance, high temperature resistance, compression resistance, insulation, sound insulation, and low thermal conductivity. The density is generally 240-350kg/ m3. It is used as a cement lightening agent, mixed with cement to form a low-density perlite cement slurry system, which has the following characteristics:

Low density, large slurry density range, suitable for cementing with low formation pressure and easy to lose well; site construction mixing is simple and easy to operate, does not flash, does not hold up the pump, and is in low pressure, easy to leak, and long sealing sections. It has a good application prospect.

:8618937948916

:8618937948916 :Sales@lyminghong.com

:Sales@lyminghong.com Language

Language 简体中文

简体中文  English

English